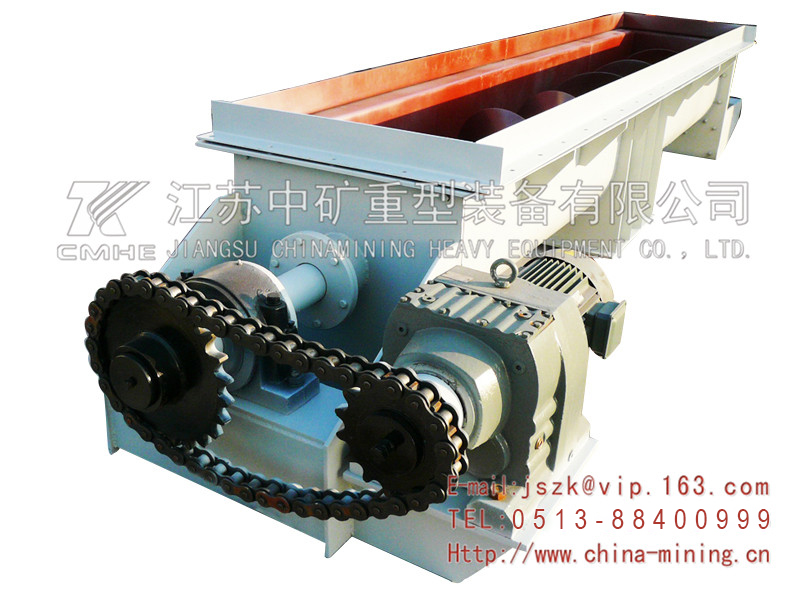

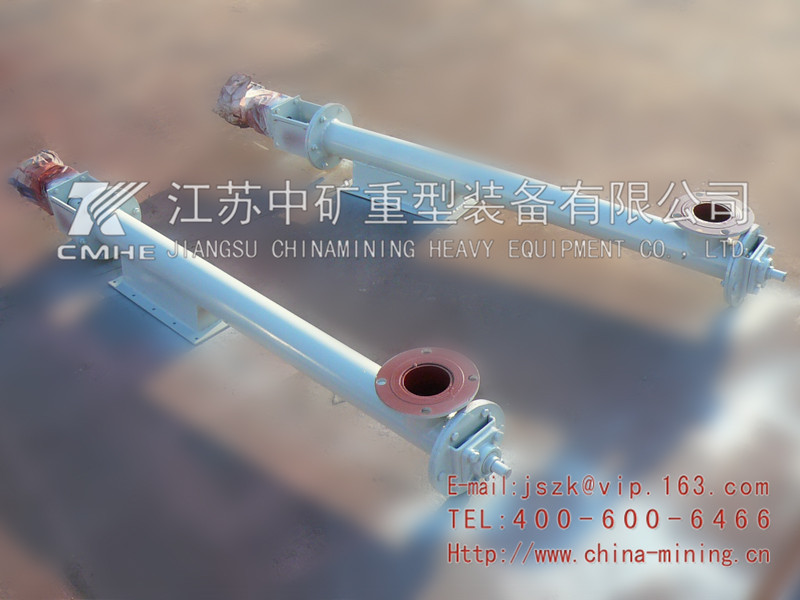

LS型螺旋輸送機

周先生 13906278080 丁寶勤 13906276368

電話:0513-88400999 傳真:0513-88400998 郵箱:jszk@vip.163.com

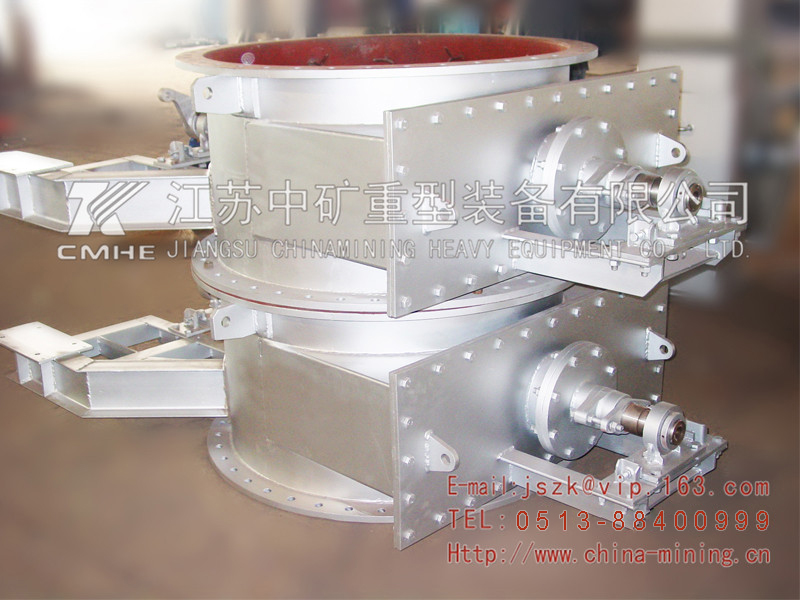

產品特點

LS型螺旋輸送機結構合理,技術指標可靠,頭部、尾部軸承移至殼外,中間吊軸承采用滾動,滑動可以互換的兩種結構,均設防塵密封裝置,出料端設有清掃裝置,整機噪聲低、適應性強,操作維修方便,進出料口位置布置靈活。

The features and applied range of type LS screw conveyor

Type LS screw conveyor is characterized by update structure, advance technology purpose, head and tail bearing outside shell. Middle hanging bearing is used rolling or sliding changeable structure. It has dust against sealing device. Outlet device is designed clean device which is characterized by low noise, strong applicability, convenient maintenance, smooth inlet and outlet arrangement.

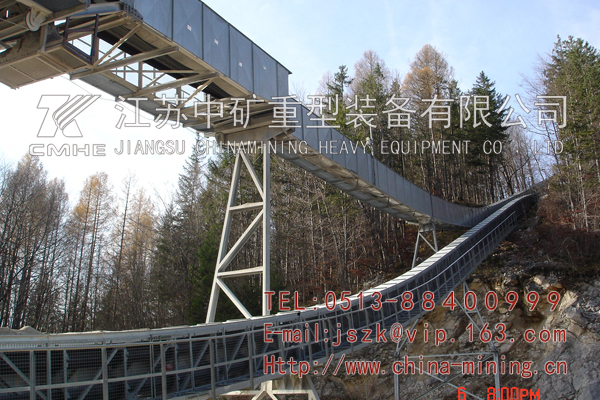

應用范圍

江蘇中礦生產的螺旋輸送機,廣泛應用于化工、建材、糧油、飼料、食品、冶金、礦山、塑料、醫藥等行業;適用于水平或小于20度傾角,輸送粉狀、粒狀和小塊狀物料,如水泥、煤粉、糧食、化肥、灰渣、砂子等,物料溫度200度以下。

LS型螺旋輸送機不宜輸送易變質、粘性大、易結塊的物料,因為這些物料在輸送時會粘結帳螺旋上,并隨之旋轉而不向前移動或者在吊軸承處形成物料的積塞,而使螺旋機不能正常工作。

LS型螺旋輸送機螺旋直徑從200毫米到500毫米,共有五種規格,長度從4米到70米,每隔0.5米一檔,選型時應符合標準公稱長度,特殊需要可在選配時另行提出。

Application range

Screw conveyor is widely used in all kinds of industry department, For example: building material, electric power, chemical industry, metallurgical, coal, Al and Mg, machinery, light industry and food stuffs etc. industry. It is used to convey powder material, grain material and small lump material such as cement, coal powder, fertilizer, dust slag and sand etc. in horizontal or less than 20 degree slope. The material temperature is below 200 centigrade.

Screw conveyor can7 t convey transmutative easily, big clay and easily lump material. When conveying these materials, they will clay in the screw. Move toward with the rotation or block material at the position of hanging bearing and make screw conveyor not work usually.

The diameter of type LS screw conveyor is from 200mm to 500mm.They are five specifications which length is 4m to 70m. There will be a shift every 0.5m. When selecting, comply with standard nominal length. If it is special need, mark it in selecting assemble part.

Two ways of screw conveyor accord to driving way.

C1 way—When the length of screw conveyor is less than 35m, use single side driving.

C2 way—When the length of screw conveyor is more than 35m, use double sides driving.

Type of middle hanging bearing for screw conveyor:

M1—Rolling and hanging bearing, Use type 80000 sealing bearing. There is a dust againt sealing structure. It is usually used in easy adding oil, no oil or oil pollution place. The sealing effect is good and the life of hanging bearing is long. The temperature of conveying material is less than 80 centigrade.(When placing an order, it may not be marked.)

M2—Sliding and hanging bearing. It is designed sealing device. It is usually used in higher temperature(over 80

or convey hydraulic material.

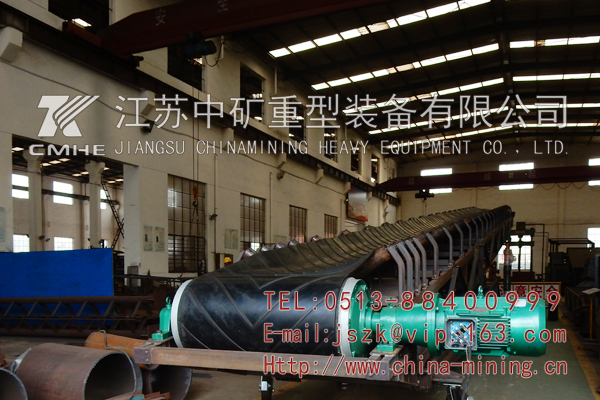

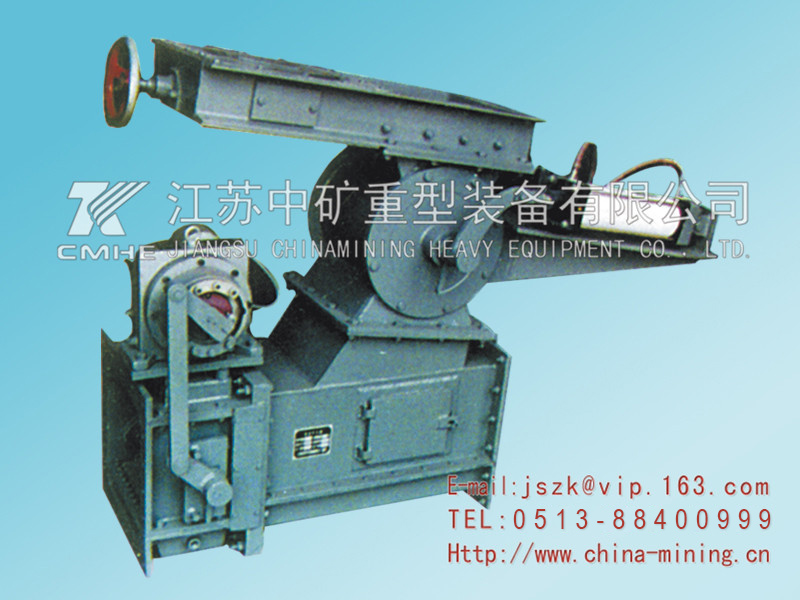

一臺螺旋機通常按驅動裝置、頭節、若干標準中部節,選配中間節,尾節順序組成,除頭節 機殼和選配節外,各節螺旋及機殼均具有互換性,在出料端螺旋有清料裝置,安裝時注意位置。

驅動裝置由一臺行星擺線針輪減速電機(或JTC減速電機)或選JZQ型減速機承擔,在頭節前部 裝有止推軸承,可承受移動物料時而產生的軸向力,頭節機殼內設吊軸承及底座,每一中間節安 有一只吊軸承用以支撐螺旋軸,吊軸承內裝有向心球軸承(或整體滑動軸承),在尾節后部裝有滾動(滑動)軸承用以支撐螺旋軸和補充螺旋長度的誤差,安裝時應從頭部開始,順序進行。

在總體布置時還應注意,不要使機座和出料口布置在機殼接頭的法蘭處,進料口也不應布置 在吊軸承的上方,如果因為開出料口影響機座的安排而不能遵循本原則時,使用單位應繪制螺旋機總圖。

Screw conveyor is made up of driving device, head node, many standard middle parts, selection middle part and tail part. Except screw and machine shell,screws and shell can be changeable. Outlet screw has clean device and note the position when installation.

Driving device is burdened with planet cycloid needle wheel reducer(or JTC reduced motor) or select JZQ reducer. There is a thrust bearing in front of head node and can bear shaft power because of moving material. Head shell is arranged hanging bearing and pedestal. Every middle node is installed a hanging bearing to support screw shaft. Hanging bearing is installed centripetal ball bearing(or whole sliding bearing),There is rolling(sliding)bearing to support screw shaft and make up of the error of screw length at the back of tail node. When installation, start from head in turn.

Note to arrange pedestal and outlet which can; t be on the connection of shell flange. Inlet E1 should not be arranged on the top of hanging bearing. If it can; t comply with the regulation, the customer should provide general drawing of screw conveyor.

1、驅動裝置及地腳尺寸(1. Driving device and foot bolt dimension)

(1)減速機選用XWD型的驅動裝置

(1) Reducer model is XWD driving device.

2、進出料口

螺旋機進料口、卸料口由用戶現場開,一般應從尾部進料,端部出料,也可從端部進料、由尾 部出料;若需從中部加料,兩端卸料,或從兩端加料,中部卸料、訂貨時需來簡圖。

(1)進料口

進料口的結構表示如下圖,進料口是用以連接螺旋機和進料漏斗的部件,其由蓋扣夾緊在機蓋 上,也可用焊接的方法與機蓋相聯,裝置進料口時應在所裝的機蓋上按進料口內孔尺寸開孔。

2. Inlet and Outlet

The structure of inlet is as the following drawing. Inlet is to connect screw conveyor and inlet funnel. The cover is clamped on the machine cover. Or connect with welding. Open the hole according to inlet inside hole on machine cover when installing inlet.

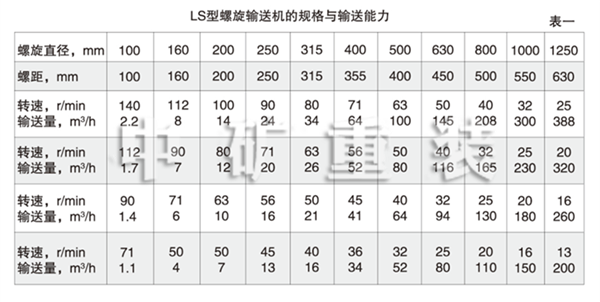

型號規格及技術參數(見表一)

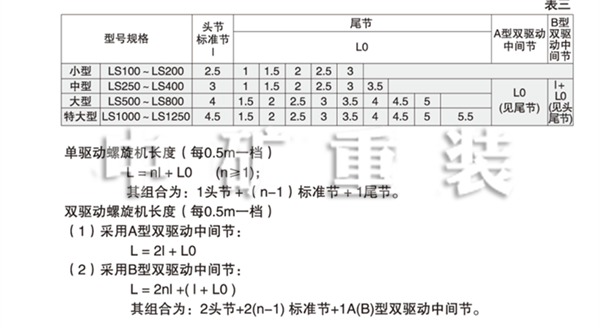

LS型螺旋輸送機分為小型、中型、大型、特大型。

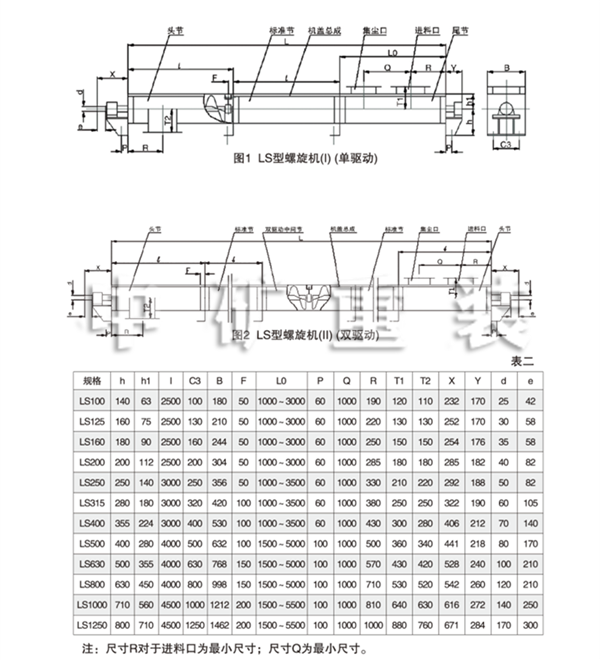

外形結構及連接尺寸

長度與組合(見表三)

一臺螺旋機通常按驅動裝置、頭節、若干標準中部節,選配中間節,尾節順序組成,除頭節機殼和選配節外,各節螺旋及機殼均具有互換性,在出料端螺旋有清料裝置,安裝時注意位置。

驅動裝置由一臺行星擺線針輪減速電機(或JTC減速電機)或選JZQ型減速機承擔,在頭節前部裝有止推軸承,可承受移動物料時而產生的軸向力,頭節機殼內設吊軸承及底座,每一中間節安有一只吊軸承用以支撐螺旋軸,吊軸承內裝有向心球軸承(或整體滑動軸承),在尾節后部裝有滾動(滑動)軸承用以支撐螺旋軸和補充螺旋長度的誤差,安裝時應從頭部開始,順序進行。

在總體布置時,還應注意不要是機座和出料口布置在機殼接頭的法蘭處,進料口也不應布置在吊軸承的上方,如果因為開出料口影響機座的安排而不能遵循本原則時,使用單位應繪制螺旋機總圖。

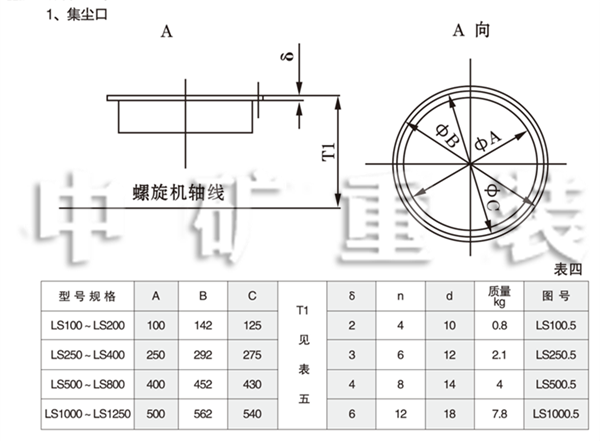

附件尺寸

1.集塵口

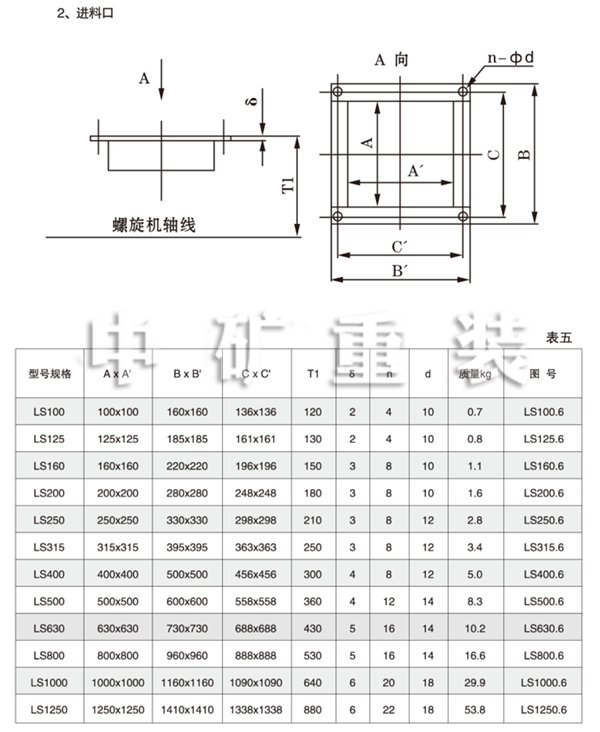

2、進出料口

螺旋機進料口、卸料口由用戶現場開,一般應從尾部進料,端部出料,也可以從端部進料、由尾部出料;若需要從中間部分加料,兩端卸料,或從兩端加料,中間卸料,訂貨時需來簡圖。

(1)進料口

進料口的結構表示如下圖,進料口是用以連接螺旋機和進料漏斗的部件,其由蓋扣夾緊著機蓋上,也可用焊接的方法與機蓋相連,裝置進料口時應在所裝的機蓋上按進料口內孔尺寸開孔。

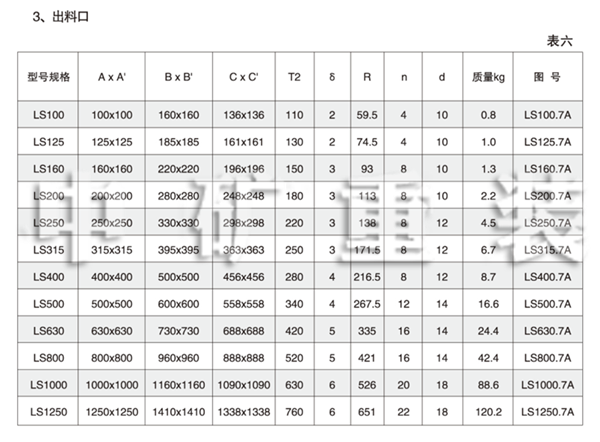

(2)出料口

出料口的結果表示如下圖,系由鋼板折成的方形管及法蘭焊接而成,不帶能關閉的出料口控制機構,在使用時將出料口焊于機殼上,其法蘭面與溜槽法蘭相連,裝配出料口的機殼還應按出料口的內孔尺寸開孔。

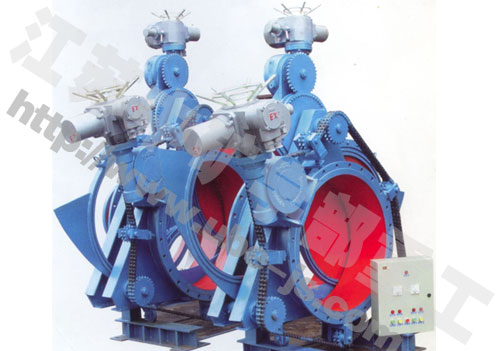

驅動裝置Drive

LS型螺旋輸送機的驅動裝置有五種形式:先是為TY型驅動裝置,由TY型同軸式硬齒面 減速器和彈性柱銷聯軸器構成,功率范圍為0.55~45kw;第二種為YZ型驅動裝置,由ZSY型 減速器,Y系列電動機,彈性柱銷聯軸器和底座構成,適用于LS630~LS1250螺旋輸送機, 功率范圍為7.5~75kw,YZ驅動裝置有丨型(右裝)和丨丨型(左裝)兩種裝配形式;第三種為YJ 型驅動裝置,有Y系列電動機與ZQ型減速器組成:第四種為YTC型驅動裝置,由YTC型同軸式 齒輪減速器與Y系列電動機組成;第五種為行星擺線減速器。

LS screw conveyor drive has five types: the first is TY-drive, composed of TY-coaxial hard-toothed surface reducer and flexible pin coupling, with a power of 0.55—45kw; the second is YZ-drive, including 卜type (right) and ll-type (left), comprised of ZSY-reducer, Y-series motor, flexible pin coupling and base, which is most applicable to LS630—LS1250 screw conveyors, with a power of 7.5-75kw; the third is YJ-drive, composed of Y-series motor and ZQ—reducer; the fourth is YTC-drive, comprised of YTC-coaxial gear reducer and Y-series motor; the fifth is planetary cycloidal reducer.