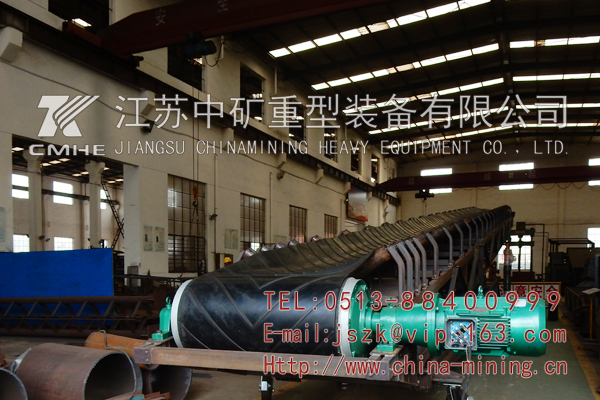

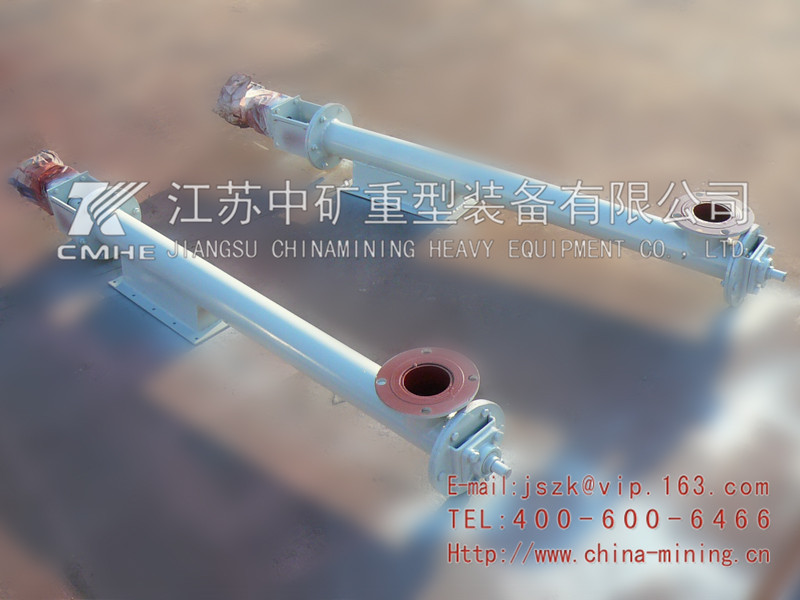

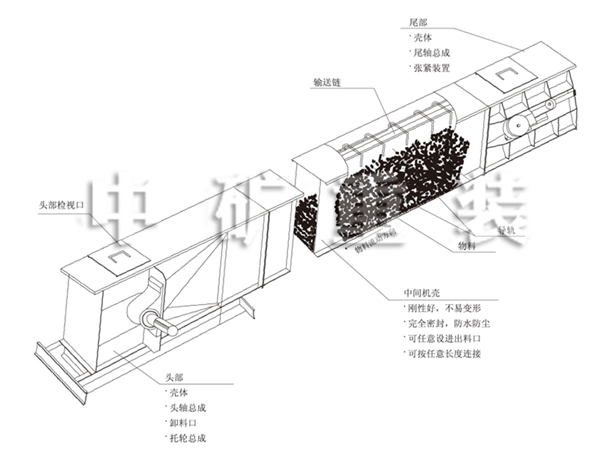

FU鏈式輸送機

周先生 13906278080 丁寶勤 13906276368

電話:0513-88400999 傳真:0513-88400998 郵箱:jszk@vip.163.com

概述 Brief Description

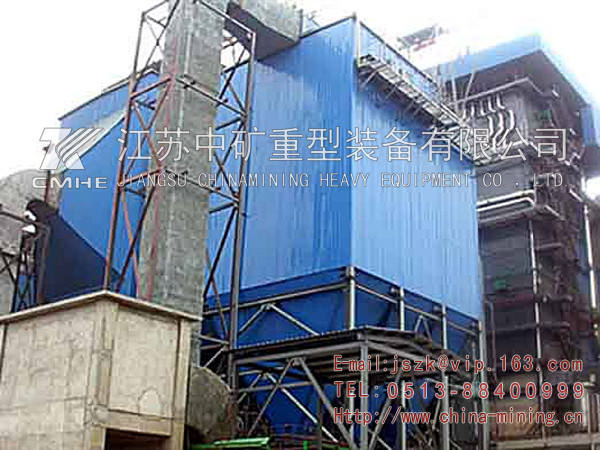

FU鏈式輸送機(簡稱"鏈式機”)結構合理,節能。是替代螺旋輸送機的一種理想產品。已 廣泛應用于建材、化工、火電、糧食加工、礦山、機械、冶煉、交通、港口、輸送等行業。

FU Chain Conveyor is a new kind of relatively complete conveyor, developed by CMHE after combining foreign advanced technologies and the advantages and disadvantages of domestic products of the same kind. It is featured by an advanced principle, a novel and reasonable structure, high efficiency and energy conservation. It is an ideal substitute for spiral conveyor, and is widely used in many industries,such as building materials, chemical, thermal power, grain processing, mining, machinery, metallurgy, communications, port, conveying, etc.

FU鏈式輸送機可輸送粉狀、粒狀、小塊狀物料等,包括:

水泥成品、水泥生料、黃砂、石灰石粉、煤粉、焦炭粉、粉煤灰、木屑、碎冰、石粉、尿素、合成肥料、肥皂粉、蘇打粉、純堿、石墨、塑料顆粒、聚乙烯、樹脂、硫酸鉀、硫化銨、粘土粉、石英粉、鐵礦粉、碎爐渣、食鹽、淀粉、小麥、棉籽、碎飼料、麥芽糖、稻谷、玉米、大豆等。

FU Chain Conveyor can convey more than 1000 kinds of powdery, granular and small lump:

materials. Typical materials are: cement clinker, cement raw material, yellow sand, limestone powder, coal powder, coke powder, fly ash, wood chips, crushed ice, stone powder, urea, synthetic fertilizer, laundry powder, soda powder, sodium carbonate, graphite, plastic particles, polyethylene, resin, potassium sulfate, ammonium sulfide, clay powder, quartz sand, iron ore powder, slag, salt, starch, cottonseed, ground feed, malt sugar, rice grains, corns, soy beans, etc.

性能特點

性能特點 | 詳細說明 |

輸送能力大 | 本機體積小、輸送能力大,它只需皮帶輸送機1/5的空間和螺旋輸送機2/3的空間就能輸送相同流量的物料。輸送能力6m3/h~500m3/h。 |

使用壽命長、費用低 | 用合金鋼材經科學熱處理加工而成的輸送鏈,其正常壽命大于5年,鏈子上滾子壽命不小于1年(易損部件),從而保證年維修量在一次一下,降低了使用費用,提高了生產效益。 |

使用能耗低 | 借助物料的內摩擦力,使運動件所做的功大部分都轉為有效功。采用鏈鉤輸送大大減少了物料對其的阻力,使其能耗僅為螺旋輸送機的30%~60%。 |

密封、安全 | 整機密封,使粉塵無處可鉆,防水防雨,操作方便、安全,運行可靠。 |

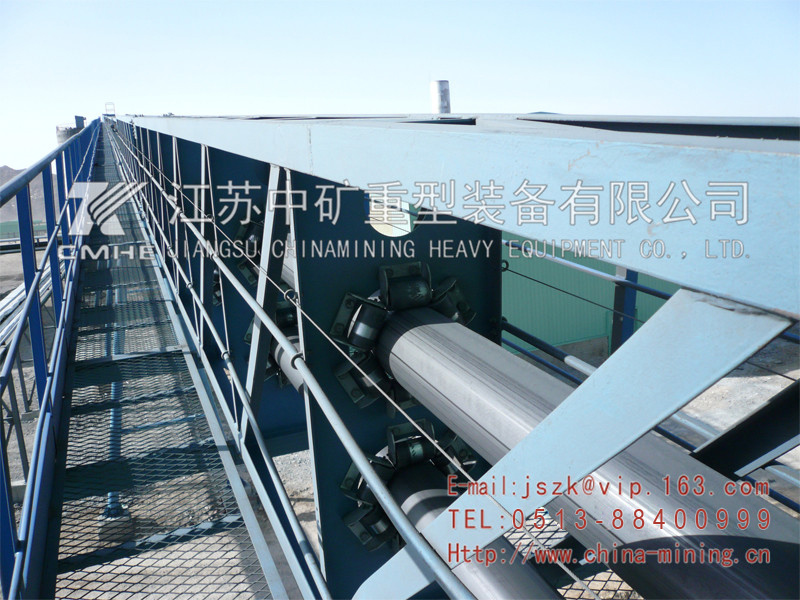

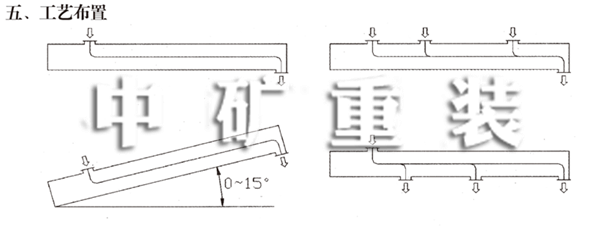

工藝布置靈活 | 允許在機殼任何位置選擇多種形式的進出口料口,可高架、地面或地坑布置,可水或平爬坡(≤15°)安裝。 |

工藝布置

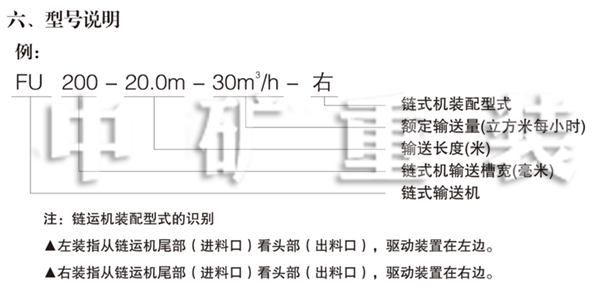

型號說明

主要技術參數

表1.各種機型鏈運機技術參數

型號 | 槽寬 (mm) | 理想 粒數 (mm) | 10%粒數 (mm) | 基本輸送量(m3/h) | 物料濕度(理論) | |||||

鏈 速 | ||||||||||

11 | 13.5 | 17 | 21 | 22.7 | 28 | |||||

FU150 | 150 | <4 | <8 | 10 |

| 16 |

| 20 |

| ≤5%以手捏成團撒手后仍不能松散為度 |

FU200 | 200 | <5 | <10 | 20 |

| 30 |

| 40 |

| |

FU270 | 270 | <7 | <15 | 35 | 45 | 55 |

| 70 | 80 | |

FU350 | 350 | <9 | <18 |

| 70 | 85 | 100 |

| 130 | |

FU410 | 410 | <11 | <21 |

| 90 | 110 | 138 |

| 175 | |

FU500 | 500 | <13 | <25 |

|

| 170 |

| 210 | 270 | |

FU600 | 600 | <15 | <30 |

| 184 | 224 |

| 276 | 340 | |

FU700 | 700 | <18 | <32 |

| 250 | 305 |

| 376 | 460 | |

基本輸送量是以水泥等為物料制定的,實際輸送量可掌握在此表中推薦值小于0—20%范圍內。當用于其他行業輸送磨琢性小,且溫度<60℃的物料時,鏈速還可加快(鏈速可達40m/min,參見表2)。具體可與江蘇中礦技術部聯系。聯系電話:0513-88400999。

表1.各種機型鏈運機技術參數

型號 | 槽寬 (mm) | 理想 粒數 (mm) | 10%粒數 (mm) | 基本輸送量(m3/h) | 物料濕度(理論) | |||||

鏈 速 | ||||||||||

11 | 13.5 | 17 | 21 | 22.7 | 28 | |||||

FU150 | 150 | <4 | <8 | 10 |

| 16 |

| 20 |

| ≤5%以手捏成團撒手后仍不能松散為度 |

FU200 | 200 | <5 | <10 | 20 |

| 30 |

| 40 |

| |

FU270 | 270 | <7 | <15 | 35 | 45 | 55 |

| 70 | 80 | |

FU350 | 350 | <9 | <18 |

| 70 | 85 | 100 |

| 130 | |

FU410 | 410 | <11 | <21 |

| 90 | 110 | 138 |

| 175 | |

FU500 | 500 | <13 | <25 |

|

| 170 |

| 210 | 270 | |

FU600 | 600 | <15 | <30 |

| 184 | 224 |

| 276 | 340 | |

FU700 | 700 | <18 | <32 |

| 250 | 305 |

| 376 | 460 | |

基本輸送量是以水泥等為物料制定的,實際輸送量可掌握在此表中推薦值小于0—20%范圍內。當用于其他行業輸送磨琢性小,且溫度<60℃的物料時,鏈速還可加快(鏈速可達40m/min,參見表2)。具體可與江蘇中礦技術部聯系。聯系電話:0513-88400999。

表2:輸送不同磨琢性物料所推薦的鏈速

物料磨琢性 | 特大 | 大 | 中 | 小 | |

鏈速m/min | 推薦 | 10 | 15 | 20 | 30 |

zui大 | 15 | 20 | 30 | 40 | |

表3:輸送水泥生熟料和成品粉料的適宜鏈速

物料 | 生料細粉或水泥成品 | 熟料細粉或水泥成品 | 生產或熟料粗粉回料 | |

料溫 | <60℃ | 16℃~120℃ | <60℃ | 60℃~120℃ |

適宜鏈速m/min | 15~20 | 10~15 | 10~13.5 | 10~12 |

鏈速m/min | 25 | 17 | 15 | 14 |

表4:傾斜輸送時的折扣系數η值

傾角(度) | 0~2.5 | 2.5~5 | 5~7.5 | 7.5~10 | 10~12.5 | 12.5~15 |

η | 1 | 0.95 | 0.9 | 0.85 | 0.8 | 0.7 |

注:當鏈運機傾斜放置時,輸送量將減少,這時,實際輸送能力為表1的數值乘以折扣系數η值。

設備選用及注意事項

VI. Equipment selection and do' s and don' ts

(一)、設備選用

1、Equipment selection

正確合理地選型和使用保養才能發揮設備的性能。在選用F U鏈式輸送機時,應注 意以下幾個重要參數:

Only proper and reasonable choice and maintenance of the equipment can bring the advanced equipment’ s best performance into play. When choosing FU chain conveyors, pay attention to the following important specifications:

1、鏈速的選擇

1、Selection of chain speed

用戶應根據被輸送物料的性能、狀態(如:磨琢性、料溫、物料粒度)等因素選擇。對于輸送 水泥生熟原料和成品粉料的適宜鏈速可參照表3。其它與水泥性能和狀態相近的物料也可參照此表。

Users must make a choice in accordance with the conveyed material, s features and conditions (eg. wear resistance, material temperature, granularity, etc.). Table 3 can be referred to for the most appropriate chain speed of cement raw material and clinker and finished powder. It1 s also applicable to other materials with features and conditions similar to cement’ s.

2、機型的選擇

2、Selection of model

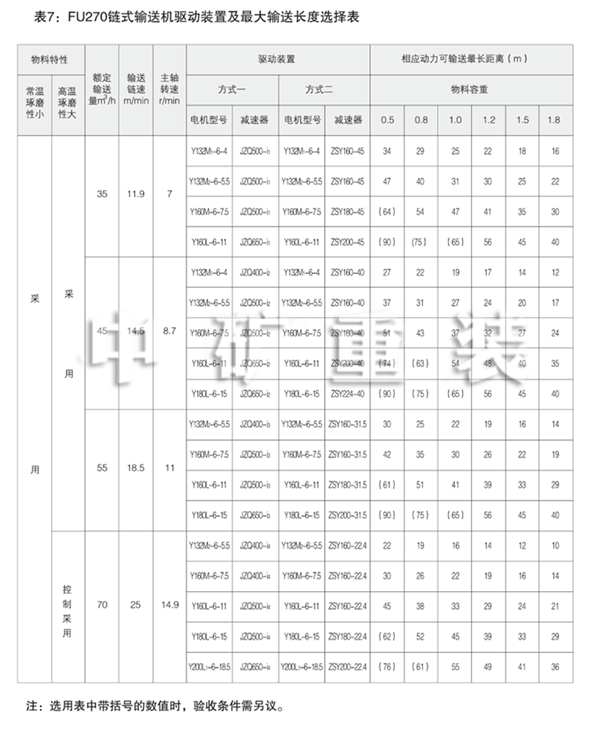

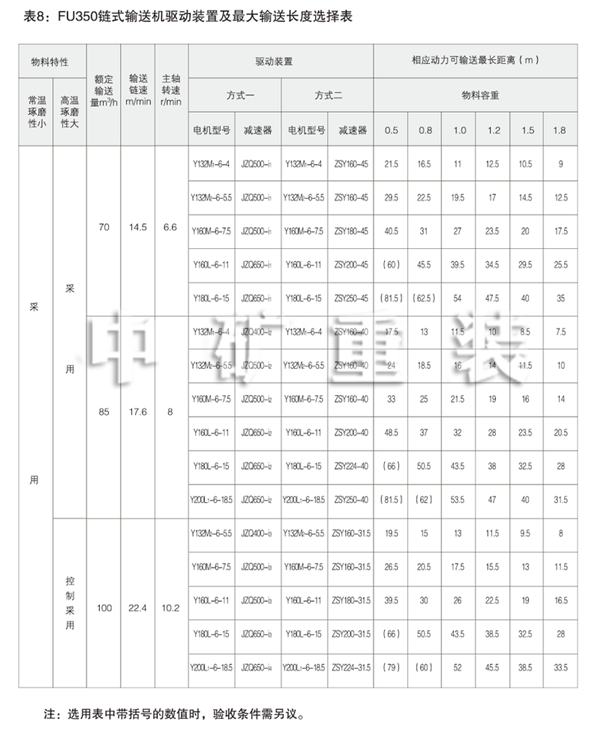

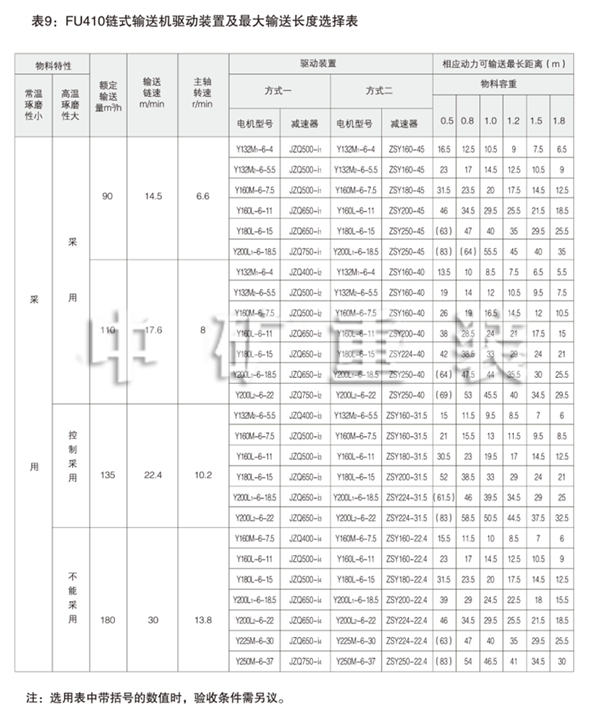

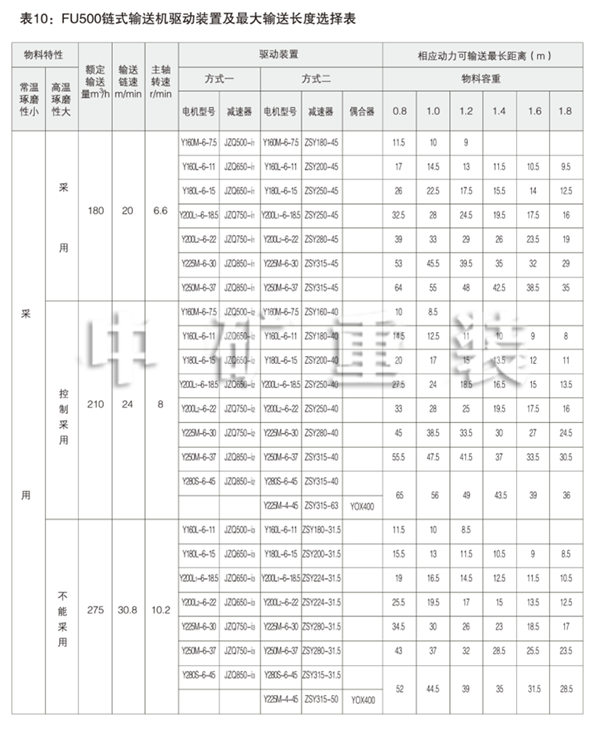

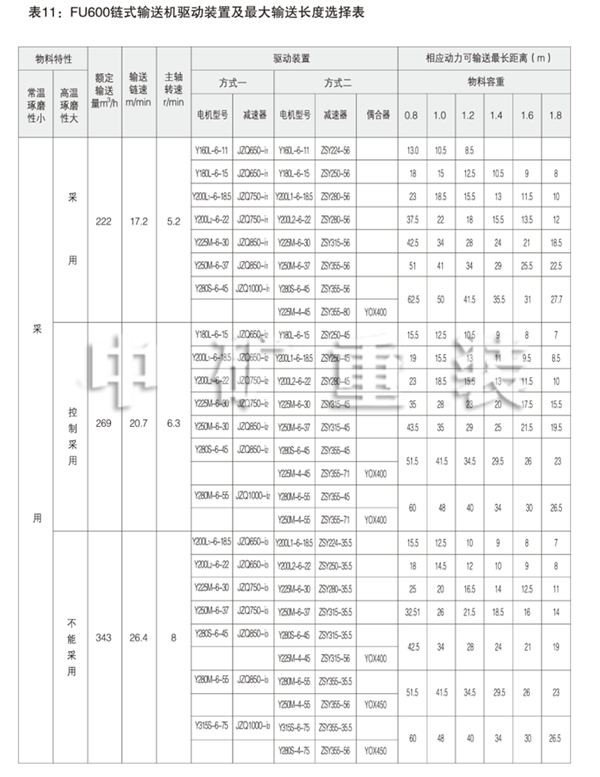

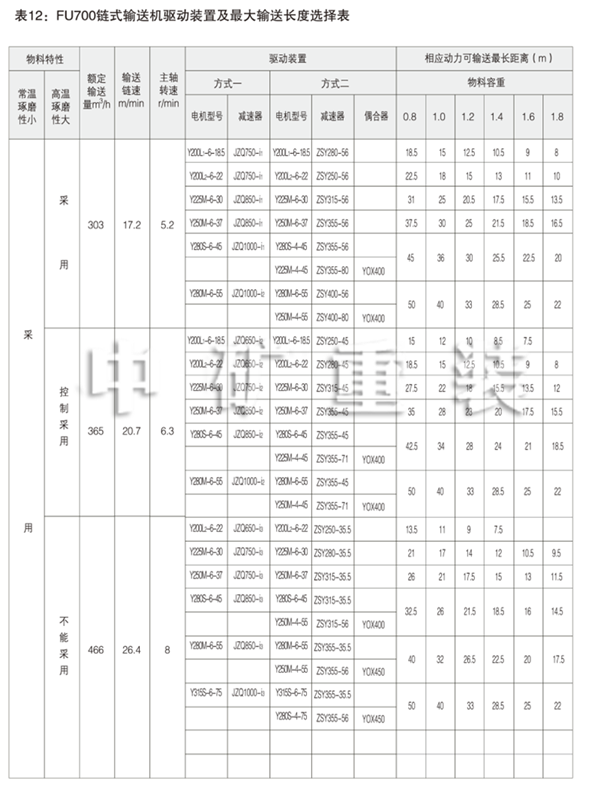

鏈速確定后,即可根據輸送置選擇理想機型。每種機型都有基本輸送置(見表1 >。在機型選擇表( 即表5 ~ 1 2 )中還列出輸送量、輸送長度和動力的選擇,必須指出,在相同輸送量下,選擇 稍大機型可使鏈速降低,從而延長使用壽命,但輸送量也不宜過小,如實際量低于該機輸送量3 0% 以上時,使用時會發生料層過薄,內壓力過小,造成空轉,反而增加磨損。

After the chain speed is decided, choose the best model according to the conveying capacity. Each model has a general conveying capacity (see Table 1). There are also optional max conveying capacities, max conveying distances and powers in Table 5-12. It must be pointed out that the larger models with the same conveying capacity may decrease the chain speed and extend service life. However, the conveying capacity should not be too small. If the actual capacity is over 30% of the conveying capacity of this conveyor, idling would happen for the too thin material layer and too small inner pressure, which would increase wear and tear instead.

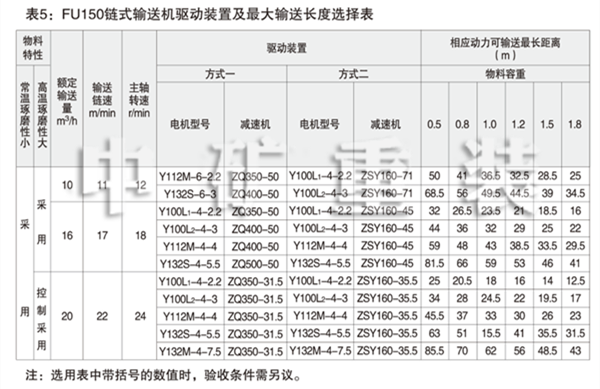

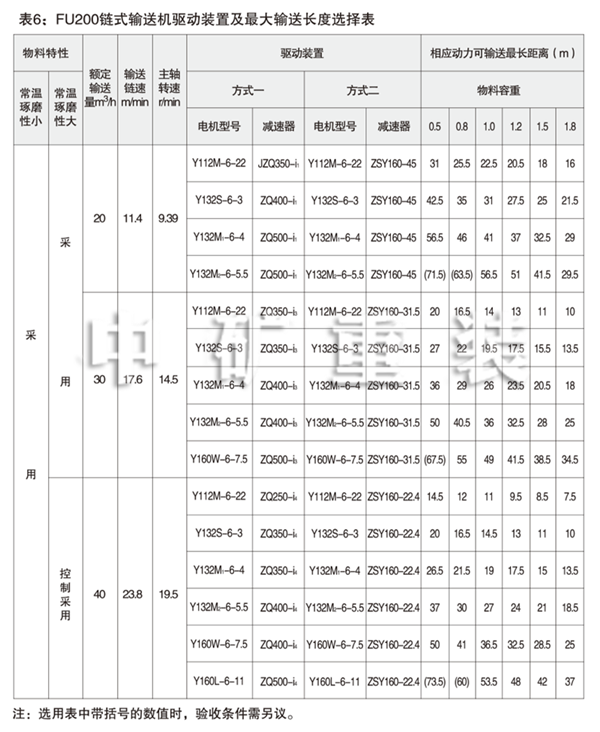

3、動力的選擇

3、Selection of power

選定機型后,可根據輸送量,輸送長度和工藝布置狀況(參照表5 -12)選擇動力和減速機速比及 裝配型式。

After the model is decided, choose power, reduction ratio and assembling type in accordance with the conveying capacity, conveying distance and layout (see Table 5-12).

選擇驅動裝置時,可以選擇表中列出的Y系列6級電動機+ J ZQ系列減速器,或選用Y系列6級電 動機+ZSY系列減速器或者直接選用擺線針輪減速電機。

Y-series 6-polar motor +JZQ series reducer, Y-series 6-polar motor +ZSY series reducer, or cycloidal gear reducer are optional.

小規格建議采用JZQ系列配置即方式。

If small specification, JZQ series are advised.

驅動功率在45KW以上時,建議使用Y系列4級電動機+液力藕合器+ZSY系列減速器(采取直聯)。

When the drive power is over 45kw, Y-series 4-polar motor+fluidcoupling+ZSY-series reducer (direct connection) is advised.

驅動裝置的裝配型式有:左裝、右裝及背裝式(僅適用于功率在5.5KW以下的XWD擺線針輪減速 電機)。

Drive installation type: left, right and back (only applicable to XWDcycloidal gear reducer with a power of below 5.5kw).

4、進出料口的選擇

Selection of inlet and outlet

各進出料口的尺寸(見圖二),用戶根據需要進行選擇,在選擇時必須注意:

See Figure 2 for all the different sizes of inlets and outlets. Clientsmake a selection as required. When making a choice, notice:

*對于流動性差或濕度大的物料,一般不宜采用上進料口,以免進料不暢。

For the materials with poor flowability and high humidity, it is betternot to use the upper charge inlet in case of unsmooth charging.

*由于工藝布置的限制。當Diyi只進料口離尾軸較近(不能保證距離Um i n )時,一般 不宜采用上進料口。

If the first inlet is too close to the tail shaft (closer than theminimum distance Umin), it is better not to use the upper inlet.

*本機可用多個進料口和多個出料口,此外還可根據用戶需要,提供帶閘出料口。

* This conveyor is able to have several inlets and outlets. Besides,the inlet with a valve is available if needed.

*兩臺鏈運機上下交叉銜接時,應分別采用中間節底面出料口(有帶閘的和不帶閘的兩種) 和兩側進料口。

When two chain conveyers are crossing connected from up and down, theyboth should separately have an outlet in the bottom surface of themiddle section (two kinds with and without a valve available) and inleton either side.

(二)注意事項

Do,sand don,ts

*輸送物料的粒度應符合(表1)中的規定。

*The material granularity should meet the specifications in Table 1.

*物料溫度在6 0七~ 1 2 0七時,宜選用較慢鏈速。物料溫度超過1 2 0 C時,請與中礦公司 技術部聯系,聯系人:周小姐,聯系電話:0513-8840099 9。

When the material temperature is between 60° and 120°,slower chainspeed is appropriate. If the material temperature is over 120°,pleasecontact our Technology Dept. Contact: Ms. Zhou. Tel: 0513-88400999.

*傾斜(<151)輸送時,輸送量將減少,其實際輸送量為(表5?12)中查得的數值再乘以 折扣系數T1 (見表4),當傾斜角>4C時,必須采用傾斜型鏈條(訂貨時在合同中注明)。

*lf the inclination is ^15° , the conveying capacity will decrease, and the actual capacity is the values in Table 5-12 times the discount factor ti (see Table 4). When the inclination is > 4° C, inclined type chain must be used (indicated in the order contract).

*若選用輸送長度大于表5?12中的長度 (小于90m>或輸送一些特殊物料、或用在特殊 的場合,用戶無法自行選定時,請與中礦公司技術部聯系,聯系人:周小姐,聯系電話: 0513-88400999。)

*ln the cases of conveying distance longer than the max distances in Table 5-12 (shorter than 90 m), conveying some special materials or working in some special places, if clients cannot decide which to choose, please contact our Technology Dept. Contact: Ms Zhou. Tel: 0513-88400999.

七、驅動配置及輸送長度選擇表 VII. Drives and max conveying distances.

表5: FU150鏈式輸送機驅動裝置及輸送長度選擇表 Table 5: FU150 Chain Conveyor Drives and Max Conveying Distances

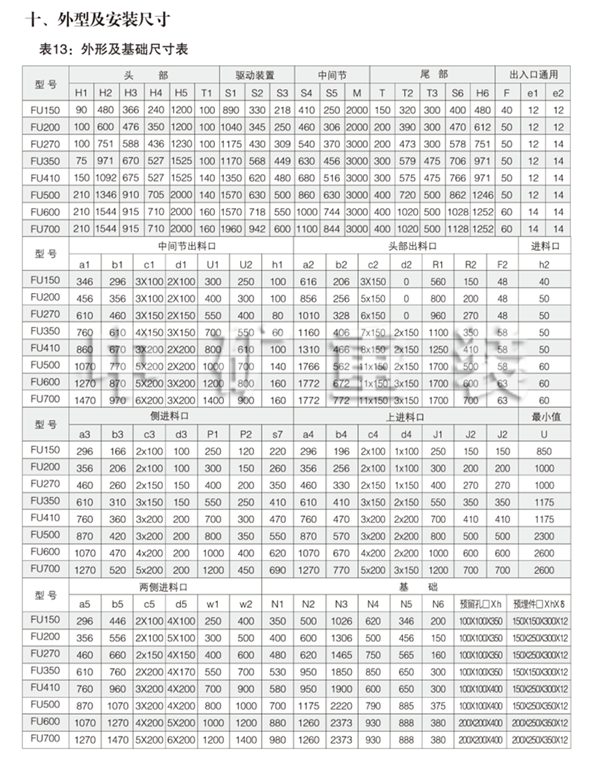

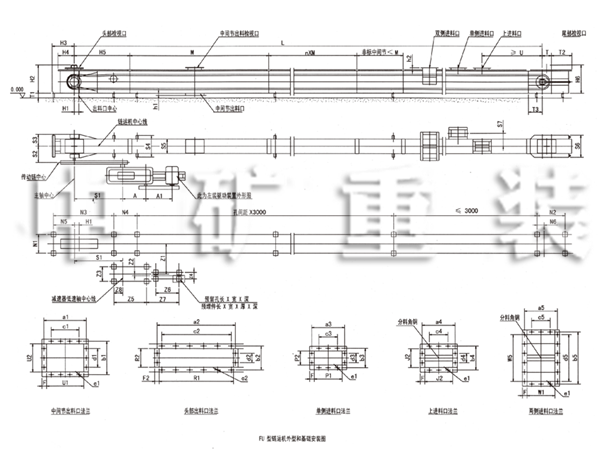

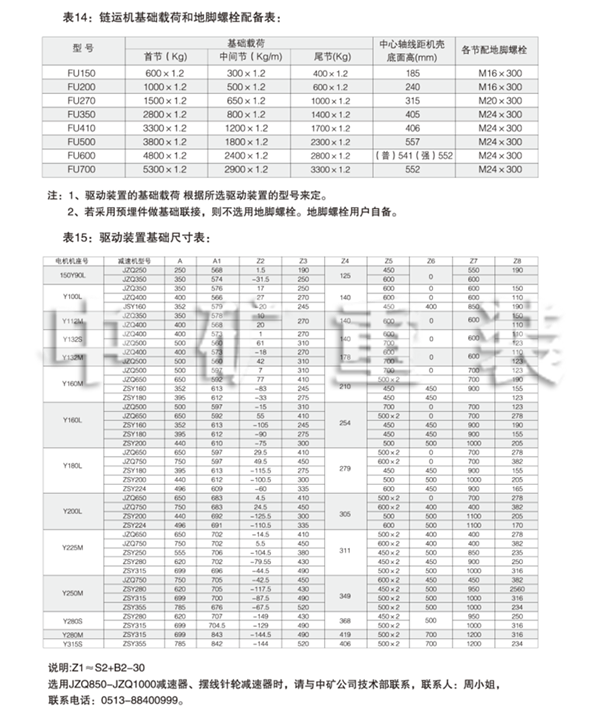

外型及安裝尺寸