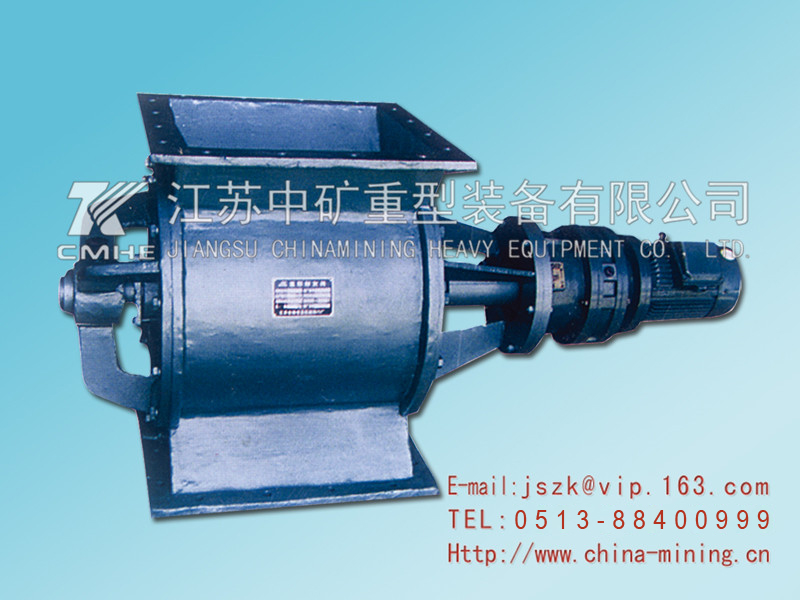

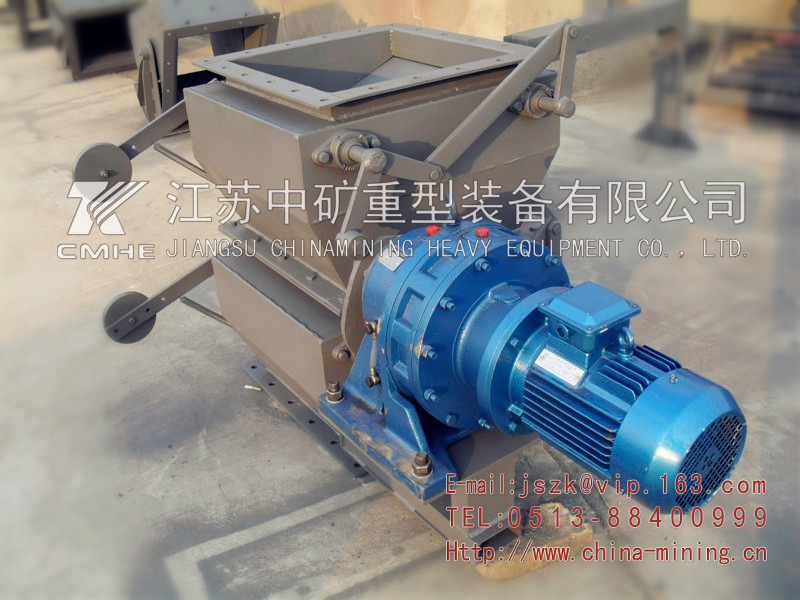

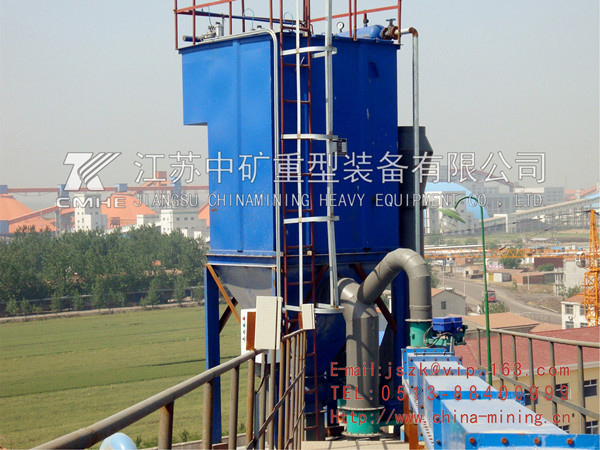

JSX圓形鎖氣翻板卸灰閥

丁寶勤 13906276368(技術) 周龍泰 13606279370(商務)

電話:0513-88400999 傳真:0513-88400998 郵箱:jszk@vip.163.com

結構特點

鎖氣翻板卸灰閥為上下交替開閉,自動復位機構。分為:z為重錘自動復位機構,具有運轉平穩、節 能,卸灰量大、小可調,卸灰、鎖氣可靠之功能。C為吊錘自動復位機構,具有占地面積省、節能,卸灰 調節方便,卸灰、鎖氣可靠之功能。B為凸輪、連桿傳動,重量自動復位機構;D為凸輪連桿傳動,彈簧 自動復位機構,結構緊湊、設計合理、運轉平穩,卸灰、鎖氣可靠。是各種無粘度的固體粉料,小于<!> 10mm的顆粒料,晶體料,團狀料,給、卸料工況的理想設備。I型為單板卸料,Ⅱ型為雙板卸料。

Structure features

Air lock and dust discharge valve open or close in turn up and down. Z is hammer automatic restore structure which is characterized by stable driving, saving energy, large discharge dust, small adjustment dust discharge and air lock. C is hammer automatic restore structure which is characterized by small area, saving energy, convenient adjustment and dependable discharge dust and air lock. B is cam wheel, pole driving and weight automatic restore position structure. D is cam wheel pole driving, spring automatic restore structure, tight structure, reasonable design, stable driving, dust discharge and dependable air lock. It is used no clay liquid powder material and less than 010mm grain, crystal and agglomerate material. It is an ideal equipment for inlet and outlet. Type I is single plate discharge and type II is double plate discharge.

技術參數表(Capacity parameter)

| 適用介質 | 工作溫度 | 卸灰量 |

| 干燥粉塵 | 150℃ | 3-168m3/h |

工作原理:

快速翻板卸灰閥主要由閥體、閥板、閥軸、搖桿等零件組成,Ⅰ型為單層,隨電氣控制糸統設定的程序,通過推桿動作推動搖桿帶動閥板開啟卸灰,然后關閉。Ⅱ型則是通過推桿推動搖桿帶動閥板開啟卸灰與鎖氣,隨電氣控制糸統設定的程序,可以使上、下閥板交替開啟、關閉。這樣兩個動作使管道上閥板始終有一個是關閉狀態,可使卸灰與鎖氣同時達到目的。

JSX系列外形連接尺寸

JSX Series Outline connected size

DN | D | D1 | H1 | H2 | LI | L2 | L3 | n-d | 傳動裝置Driving device | 功率 Power |

150 | 230 | 195 | 500 |

| 460 |

| 1400 |

| BWY-15-59 | 0.6 |

200 | 280 | 245 | 600 |

| 500 |

| 1500 | 8-Φ10 | BWY-15-59 | 0.6 |

220 | 300 | 265 | 620 |

| 520 |

| 1540 | 8-Φ10 | BWY-15-59 | 0.6 |

250 | 350 | 305 | 650 |

| 560 |

| 1610 | 12-Φ10 | BWY-18-71 | 0.8 |

300 | 400 | 355 | 750 | 540 | 600 | 1220 | 1840 | 12-Φ10 | BWY-22-71 | 1.1 |

320 | 420 | 375 | 780 | 560 | 620 | 1260 | 1980 | 12-Φ12 | BWY-22-71 | 1.1 |

400 | 500 | 455 | 950 | 700 | 815 | 1500 | 2060 | 16-Φ12 | BWY-2215-121 2215-121 | 1.66 |

450 | 550 | 505 | 1050 | 800 | 840 | 1550 | 2180 | 16-Φ12 | BWY-2215-121 | 1.66 |

500 | 600 | 555 | 1150 | 850 | 870 | 1600 | 2210 | 20-Φ14 | BWY-2215-121 | 1.66 |

600 | 700 | 655 | 1350 | 980 | 960 | 1920 | 2310 | 20-Φ14 | BWY-2215-121 | 1.66 |

720 | 820 | 775 |

| 1120 |

| 2220 | 2380 | 20-Φ14 | BWY-2715-121 | 3.18 |

800 | 900 | 855 |

| 1260 |

| 2520 | 2420 | 24-Φ14 | BWY-2715-121 | 3.18 |

1000 | 1130 | 1070 |

| 1500 |

| 2940 | 2640 | 28-Φ18 | BWY-3322-187 | 4.3 |

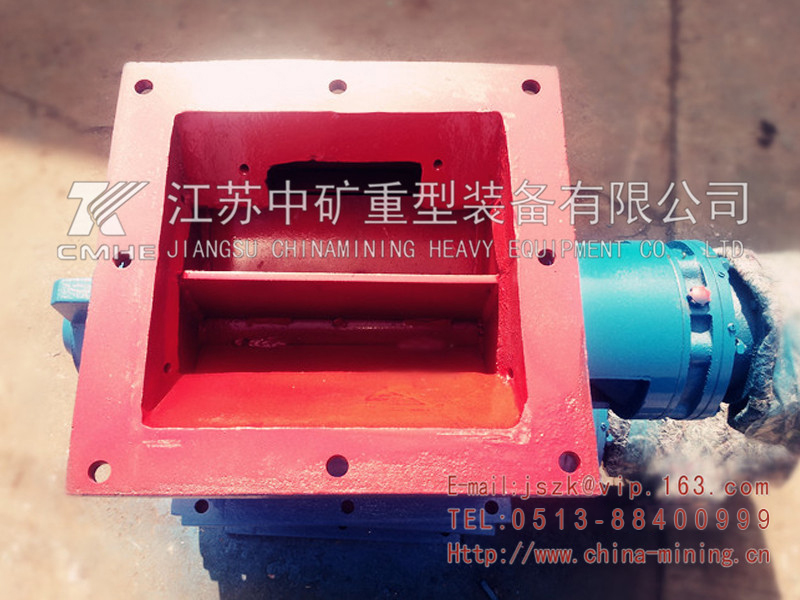

工作原理

快速翻板卸灰閥主要由閥體、閥板、閥軸、搖桿等零件組成。I型為單層,隨電氣控制系統設定的程序,通過推桿動作推動搖桿帶動閥板開啟卸灰,然后關閉。M型則是通過推桿推動搖桿帶動閥板開啟卸 灰與鎖氣,隨電氣控制系統的設定程序,可以使上、下閥板交替開啟、關閉。這樣兩個動作使管道上閥 板始終有個是關閉狀態,可使卸灰與鎖氣同時達到目的。

重錘鎖氣翻板卸灰閥主要由閥體、閥板、閥軸、搖桿、重錘等零件組成,利用力矩平衡的方法實現 鎖氣卸灰。即當作用于翻板上的物料產生的力矩大于重錘搖桿產生的力矩時,閥板打開卸灰,一旦積灰 卸去后,重錘與搖桿產生的力矩使閥板迅速關閉,實現鎖氣是由于本閥采用的是雙層結構,因而使管道 上閥板始終有一個是關閉狀態,可使卸灰與鎖氣同時達到目的。

電動鎖氣翻板卸灰閥主要由閥體、閥板、閥軸、搖桿、連桿、凸輪、彈簧等零件組成,利用凸輪、 連桿、彈簧連續動作實現鎖氣卸灰,凸輪系統由電氣控制,因而閥板的開啟角度和時間可由減速裝置控 制在一定范圍內。減速裝置帶動凸輪旋轉至上半圈時,上層閥門的連桿機構互動,閥板逐漸打開卸灰, 隨著凸輪的旋轉,彈簧機構使閥板逐漸關閉復位;凸輪旋轉至下半圈時,下層閥門的連桿機構互動,閥 板逐漸打開卸灰,隨著凸輪的旋轉又使閥板逐漸關閉,這樣兩個動作使管道上閥板始終有一個是關閉狀態,因而,可使卸灰與鎖氣同時達到目的。

Work principle

Fast flap dust discharge valve is made up of valve body, valve plate, valve shaft and rocker etc. Type I is single layer together with the set program of electric control system, push rocker to start dust discharge through handspike action, then close it. Type II is pushed rocker through handspike, start dust discharge and air lock with valve plate. Up and down valve plate start or close with setting program of electric control system. Keep one valve close in pipe. To realize dust discharge and air lock at the same time.

Hammer air lock flap valve is made up of valve body, valve plate, valve shaft, rocker and hammer etc. It can realize air lock and dust discharge with torque balance. When the torque of flap plate is over the torque of hammer rocker, valve plate is open. Once dust is discharged, the torque between hammer and rocker will make valve plate close. It can realize air lock because the valve is used double layer structure and realize dust discharge and air lock.

Motorized air lock flap dust discharge valve is made up of valve body, valve plate, valve shaft, rocker, pole, cam wheel and spring etc. It can realize air lock and dust discharge with the help of cam wheel, pole and spring continuous action. Cam wheel system is controlled by electric control. So the angle and time of valve body is controlled in some range by the reducer device. When decelerated device is rotated to up half ring, pole structure of up layer valve is acted each other. Valve is opened step by step. With the rotation of cam wheel, spring structure will make valve body restore close step by step. When cam wheel is rotated to bottom half ring, pole structure of bottom valve is acted each other. Valve plate will open and discharge valve step by step. With the rotation of cam wheel, valve plate will close step by step. Two actions of valve plate in pipe will be in close condition. So it can realize dust discharge and air lock.

安裝及調試

?安裝時傳動裝置不允許作起吊用,并嚴禁損傷。

?安裝前必須清潔閥門內腔,不允許有任何雜物和污垢附著。

?安裝前先檢查閥門各傳動部分是否完好,按用戶工作系統要求對閥門做適當的調整(出廠 時已作標準調整),試運行無誤后將閥門處于關閉狀態再進行安裝。

?法蘭連接時加密封墊后均勻鎖緊聯接螺栓。

?電動卸灰閥使用前接電源線時請注意檢查電機旋向與凸輪轉向是否正確(閥體上箭頭標明旋向),方法是:打開電機防護罩,手動旋轉葉片,調整凸輪旋向至箭頭位置,然后點動電機,看凸輪旋向是否與閥體上箭頭一致,當凸輪旋向正確后方可連續開機使用,否則易造成設備損壞。調試階段先試3小時,運行無誤后才能投人生產使用。

?重錘卸灰閥根據客戶實際工況需要調整重錘的位置來保證每次的下料量及下料頻率。

Installation and commissioning

?When installation, not allow to use driving device as hoisting tool and prohibit damage.

?Before installation, clean stomach of valve, not allow any sundries and dirt attaching it.

?Before installation, check all driving part whether they are good. Make some adjustments according to the customer' s requirement before ex-work. After test running is OK, close all valve and install them.

?When connecting flange, add sealing mat and lock connected bolt.

?Before using motorized dust discharge valve, note to check the rotation of motor whether it is the same as the cam wheel(The arrow of valve body is marked the rotated direction.)The way is to open guard of motor. Adjust the rotation of cam wheel to arrow position with rotating impeller in hand. Then start motor. Watch the direction of cam whether it is the same as valve body. When rotated direction of cam wheel is OK, start it continuously. Otherwise it will damage the equipment. Test running for 3 hours and when everything is OK, start manufacture them.

?Hammer dust discharge valve will adjust the position of hammer according to actual condition of customers and guarantee outlet output and outlet frequency.

運輸及保管

?運輸時應避免撞擊閥門,閥門應處于關閉位置以防在運輸中閥板和傳動部件損壞。

?當閥門運輸時傳動裝置及傳動部位應懸空,以防止傳動軸受力過大變形損壞。

?傳動裝置及傳動部位應作防潮、防雨處理。

?該閥應存放在干燥的室內,不允許露天存放或堆置。長期存放時應使閥門處于關閉狀態,各 傳動部位加潤滑油,傳動裝置作防潮、防塵處理。

Transport and storage

?When transporting, avoid of impacting the valve. Valve should be in close position and avoid of damaging valve plate and driving part during transporting.

?When valve is transporting, driving device and driving part should be hanging, avoid of damaging driving shaft because of larger force.

?Driving device and driving part should be weatherproof and waterproof packing.

?The valve should be stored in dry room, not allow to store or pile in open air. If the valve is storing for a long time, it should keep the valve in close condition. All driving position should add grease and driving device should packed with waterproof and dust removing.

維護及檢修

?定期檢查各傳動部位的運行情況。

?定期更換電動推桿的潤滑脂以保證其機械部分不受損壞。

?定期更換減速機潤滑油(90#機油),裝入量為容積的1 / 3。

?定期檢查閥門轉軸處的密封狀況,如發現密封問題請更換或填加石墨填料

Maintenance and repair

?Check driving condition of all driving part frequently.

?Check the grease of motorized handspike frequently and guarantee mechanical part not damaged.

?Change grease of reducer frequently(90 # machine oil).The loading capacity is 1/3of the volume.

?Check sealing condition in rotated shaft of valve. If there is something wrong with it, please replace or add graphite filling.

訂貨須知

?選用訂貨時,請參照產品樣本注明產品規格、型號、客戶選用電裝代號及技術參數(使用 溫度、設備工況、介質性質等)。

?樣本所示產品圖例及表格中所列電動裝置號為我公司基本配置,您若有特殊要求(防爆、戶外、調速、調頻)另行配置電動裝置,請參照樣本附錄中相應電裝配置說明,并加以標 注在基本型號后面。

? 選用訂貨時,若未注明客戶選用電裝代號的按我公司基本型配置,其基本型為普通型裝置,不 帶任何有關特殊要求及相關配件。

?表格中未列規格、用于特殊介質或其它特殊要求,請與我公司經銷部、技術部聯系,可為您另行設計、制造。

Notes for Order

?When placing an order, mark the specification, type, the code of electric installation for customers and techni?cal parameter(applied temperature, work condition and media characters etc.)acco「ding to product sample.

?Type of motorized device and sample drawing in the list is supplied by our company. If there is special request( Anti-explosive, outdoor, variable speed and variable frequency), buy motorized device in another. Please refer to the description of motorized device in the annex, mark it at the back of basic type.

?When placing an order, assort basic arrangement according to our company, not marking the code of electric installation. Basic type is a common device with no special request and components.

?Not specify in the list for special media or other special request, don’t hesitate to contact with sales depart?ment, technical department and we can supply the design and manufacture in another.